Superconducting RF Group

The Polarized SRF

Gun Experiment

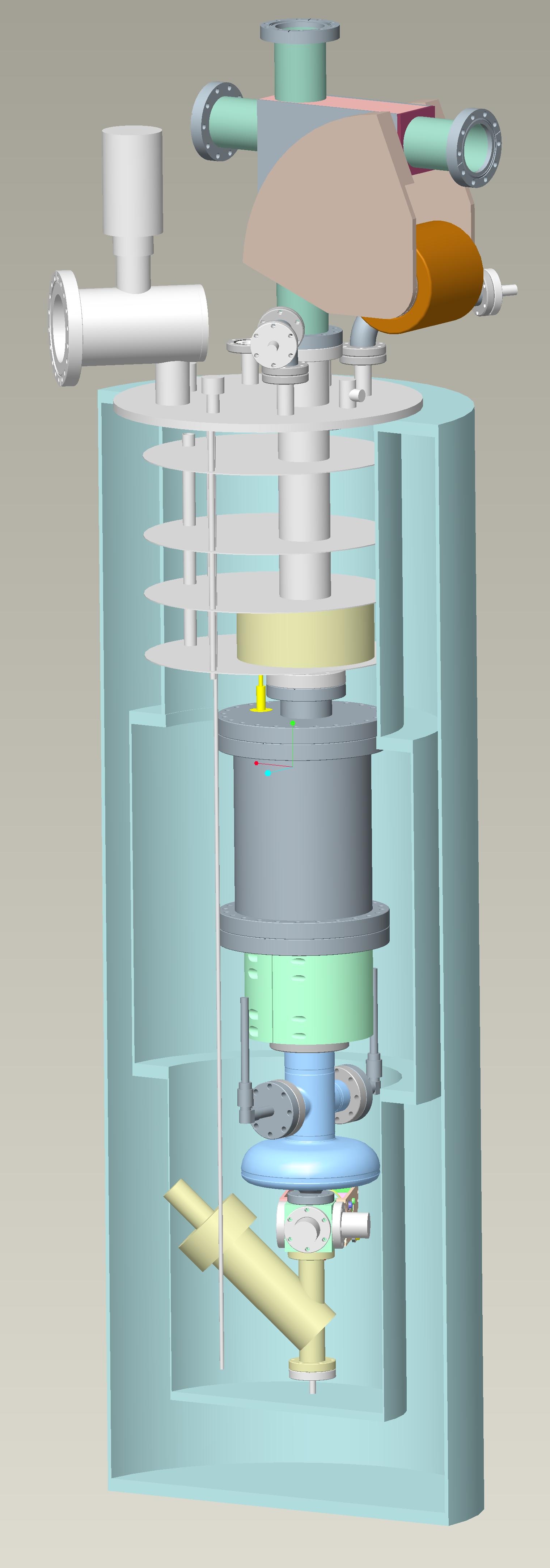

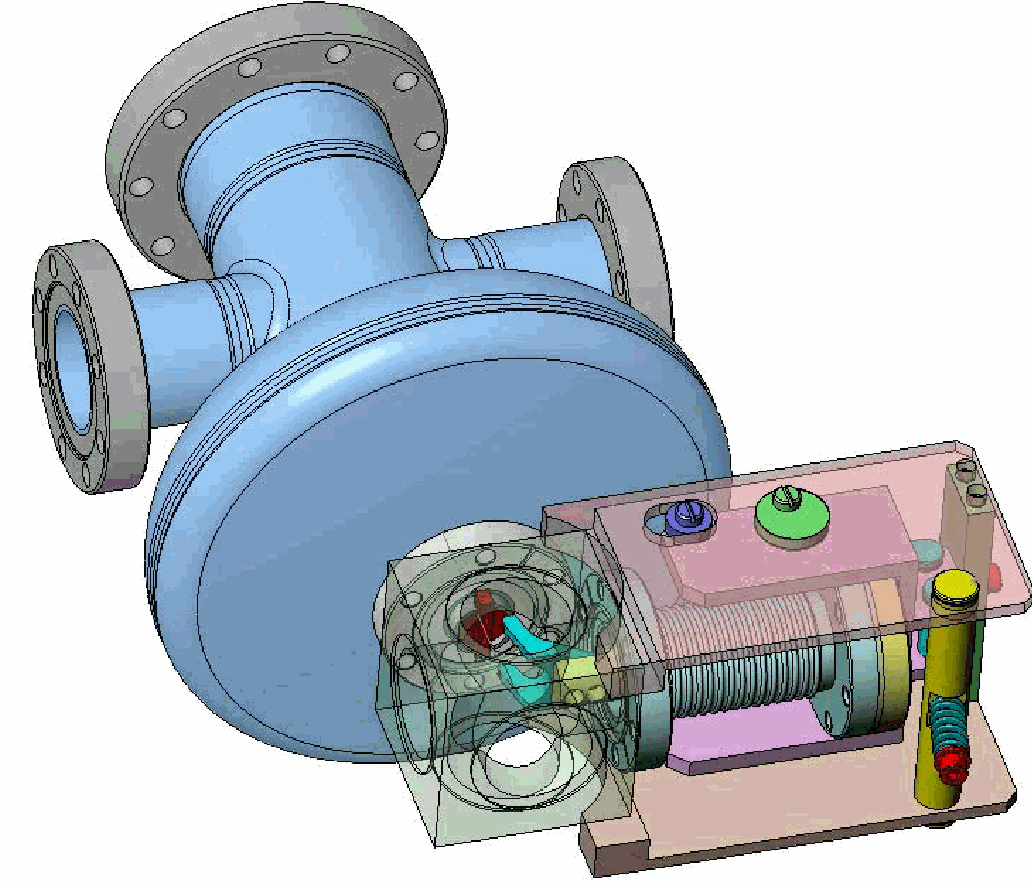

Layout: In the experiment we will operated a ˝ cell 1400

MHz SRF gun in a cryostat as shown in the picture on the left. The electron

beam will be accelerated in the gun to an energy of 0.8 MeV and exit the

cryostat on the top.

Layout: In the experiment we will operated a ˝ cell 1400

MHz SRF gun in a cryostat as shown in the picture on the left. The electron

beam will be accelerated in the gun to an energy of 0.8 MeV and exit the

cryostat on the top.

The beam pipe has a ceramic break at the exit of the gun, so that the

electron current leaving the gun can be measured. The ceramic is protected

against damage by a G10 sleeve (light green). The picture shows also (in

grey) the canister filled with NEG vacuum pump elements, which are used to

maintain ultra high vacuum when the gun is not cold. A solenoid magnet

(yellow) is used to focus the electron beam. This magnet is placed inside of

the aluminum baffles that are used as a heat shield. This position is above

the liquid helium level, but it is cold enough for high temperature

superconducting coils. Outside the cryostat the beam will be bent by 90o

using a normal conducting dipole. The beam is then sent into a Faraday cup

(not shown in this picture, coming soon). A window in the vacuum pipe above

the dipole allows shining a Laser beam onto the cathode which releases the

electrons from the cathode.

Below the gun is a valve, which is part of a mechanism allowing replacement

of the cathode.

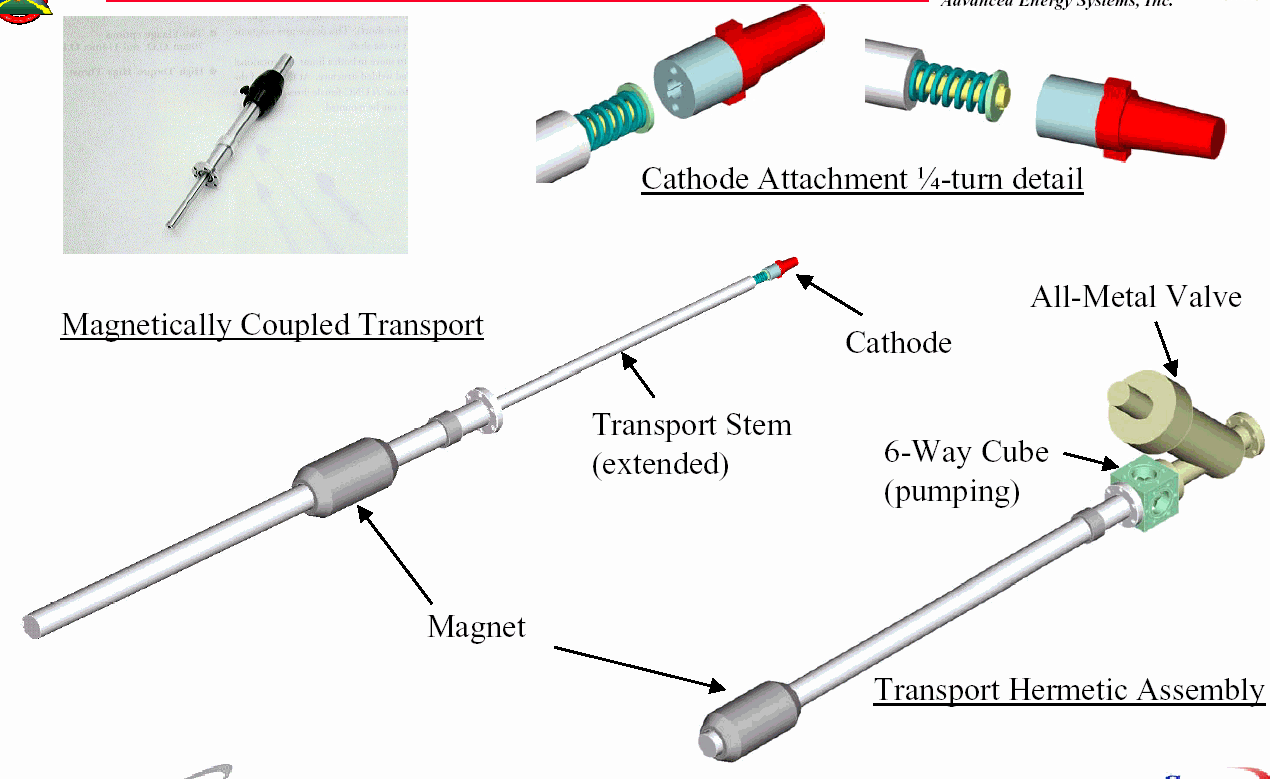

Since we expect degradation of the quantum efficiency of the cathode (this

is what we want to measure), it is important to be able to move the cathode

from the gun to a preparation chamber (shown below). This has to be done

without breaking the vacuum or the cathode will immediately be “gunked up”

by vapors of H2O, CO2, O2 and others. For

that purpose the cathode is mounted on the tip of a “cathode plug”, shown in

red in the below picture.

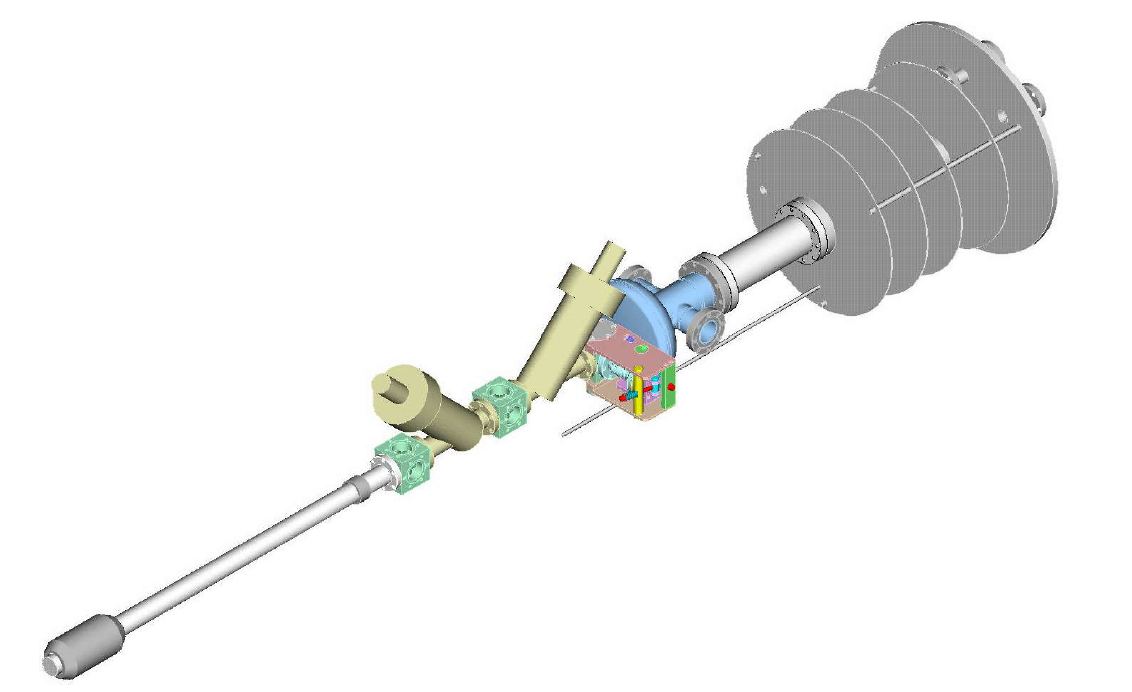

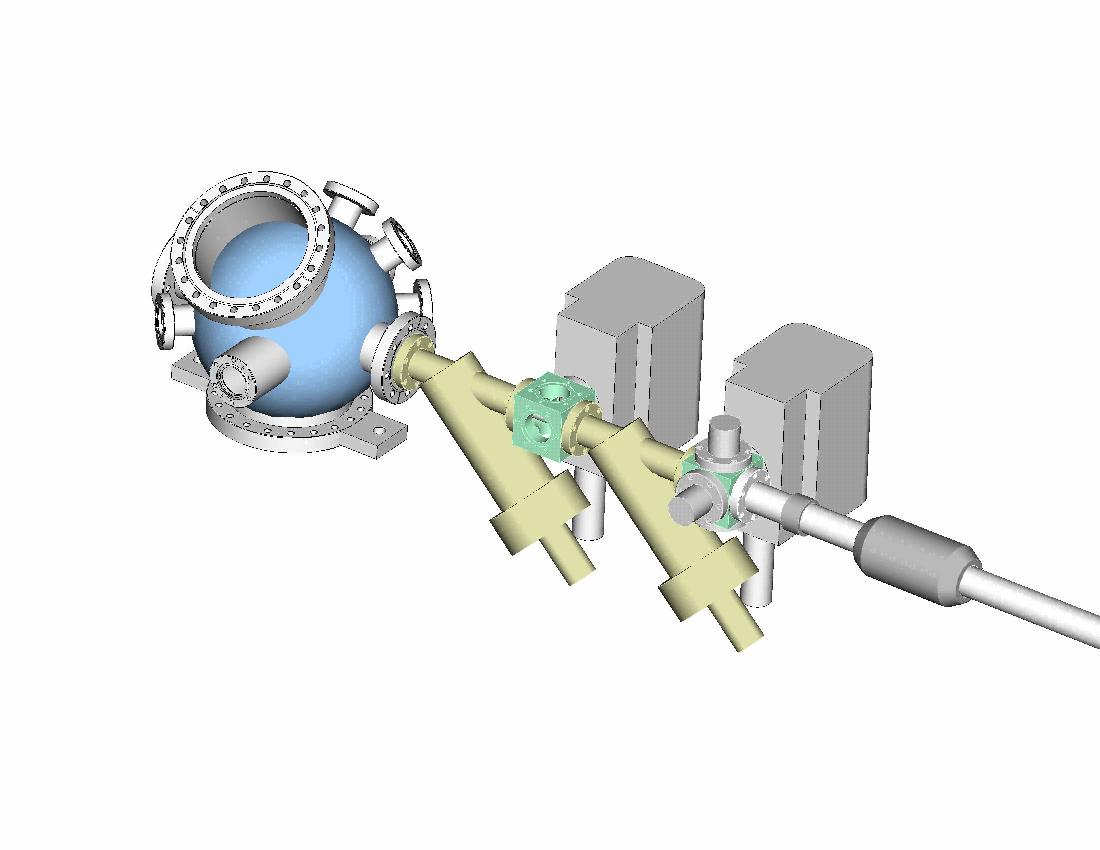

For the replacement of the cathode the gun assembly is removed from the

cryostat. A transport mechanism is connected to the gun valve. The space

between the two valves is pumped down before the valves are opened. A

magnetic actuator is then used to grab the cathode plug with a bayonet

connector and retract it into the transporter. The valves are closed and the

transporter is disconnected and then attached in the same way to a cathode

preparation chamber. After regeneration of the cathode the procedure is

repeated to move the plug back into the gun. This arrangement is designed

and will be built by AES.

Figure 1: Transport mechanism and cathode plug

Figure 2: Gun assembly with attached transporter

Figure 3: Clamp mechanism to hold cathode in place when detached from the transporter

Figure 4: Preparation chamber with attached transporter

Introduction

Cool down test in Feb 08

Time line

Publications