|

The

conventional facilities for the NASA Space Radiation Laboratory will provide

approximately 400 sq. ft. of new shielded experimental space, a 4,200 sq. ft.

laboratory support facility and a 2,800 sq. ft. Building for power supplies. It

is proposed to extract the beam from the Booster tunnel through a new 12 inch

diameter steel pipe exiting in a northerly direction. The beam will be

transported to the new experimental area through an 11 foot diameter corrugated

metal tunnel approximately 250 feet long. A concrete and corrugated metal tunnel

service structure will be provided which will also serve as an

emergency exit meeting the life safety code. The tunnels will be shielded with

15 ft. of earth cover equivalent. The

experimental area will be a reinforced concrete building with

20 ft. x 20 ft x 10 ft. high interior space.

The concrete walls, roof and floor will be four ft. thick with 11 ft. of

earth atop the facility for radiation shielding. Equipment and personnel access

is provided through a labyrinth from the laboratory support building. A concrete

beam stop will be constructed at the downstream end of the experimental area. The

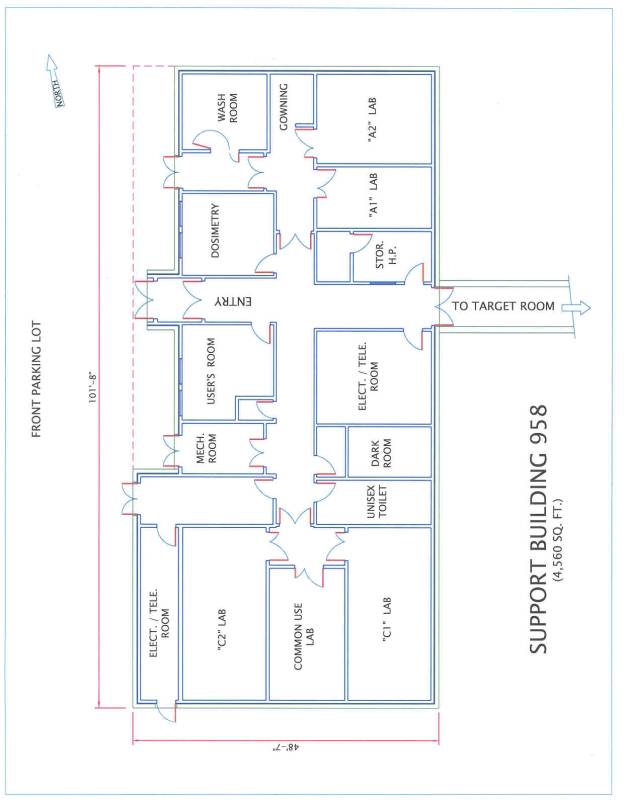

laboratory support building will be a 42 ft. x 100 ft. non-combustible

pre-engineered steel frame on concrete footings and foundations with concrete

slab on grade and a standing seam metal roof.

Exterior walls will be insulated metal panel wall construction.

Walls and roof will meet or surpass energy conservation standards with

sash of insulated double glazing in thermal break aluminum framework. Space will

be provided for two medical laboratories, two biology laboratories, including

temporary animal holding and preparation areas, a wash booth, two control rooms,

a radioactive storage area and a mechanical equipment room.

Building access and security will

be via "card" entry system and video monitoring to BNL Security???.

Parking will be provided for 20 workers. Power

supplies for the beam transport magnets and various other equipment will be

located in a separate 2,800 sq. ft. building adjacent to the transport

tunnel. Sitework

will include modifications to the existing Booster, concrete walls to retain

earth shielding, relocation of existing roadway, and parking.

Trenching, excavation, backfilling as well as relocation, extensions, and

connections to existing power, water, sanitary and storm sewers, alarm and

telephone and computer networks will all be included.

|